Sustainable production of turfgrass sod

NIBIO researcher Anne Friederike Borchert collects samples to determine the thickness and mineral soil content of turfgrass sod. Photo: Karin Juul Hesselhøe, NIBIO

Each year, between 160 and 220 ha of turfgrass sod are laid in Norway. Increased use has raised questions about whether sod production leads to loss of agricultural soil. NIBIO has recently documented how much soil is removed during sod harvest – and what producers can do to reduce this loss.

Turfgrass in Norway – scope and use

Sod has become an increasingly popular method to establish lawns in gardens, parks and sports facilities. Although the demand fluctuates with activity in the construction sector, the share of lawns established using sod is higher today than it was 10–20 years ago.

“In many housing projects there is a need for a ready-to-use lawn in a very short time. In such cases, sod is often the only realistic solution,” says Senior Researcher Trygve S. Aamlid at NIBIO.

“Admittedly, the preparatory work involving soil cultivation, precise grading and irrigation requirements are roughly the same as for direct seeding, but sodded area can be put to use much faster – usually after three to four weeks.”

Today, there are around 15 turfgrass producers in Norway, with a combined production area of 500–600 ha. Annual sales have declined slightly in recent years, from around 200 to approximately 160 ha. Production takes place mainly in Eastern Norway, but also in Agder, Rogaland and Nordland.

Concerns about soil conservation

Increased use of turfgrass sod has led to a greater attention being paid to production methods. One key question is whether sod production leads to soil loss.

In 2022, a question was raised in the Norwegian Parliament as to whether turfgrass production could conflict with Section 9 of the Soil Act, which aims to ensure that cultivated land is preserved for future food production.

“We have received similar questions from local politicians and agricultural authorities in several municipalities and counties,” says Aamlid.

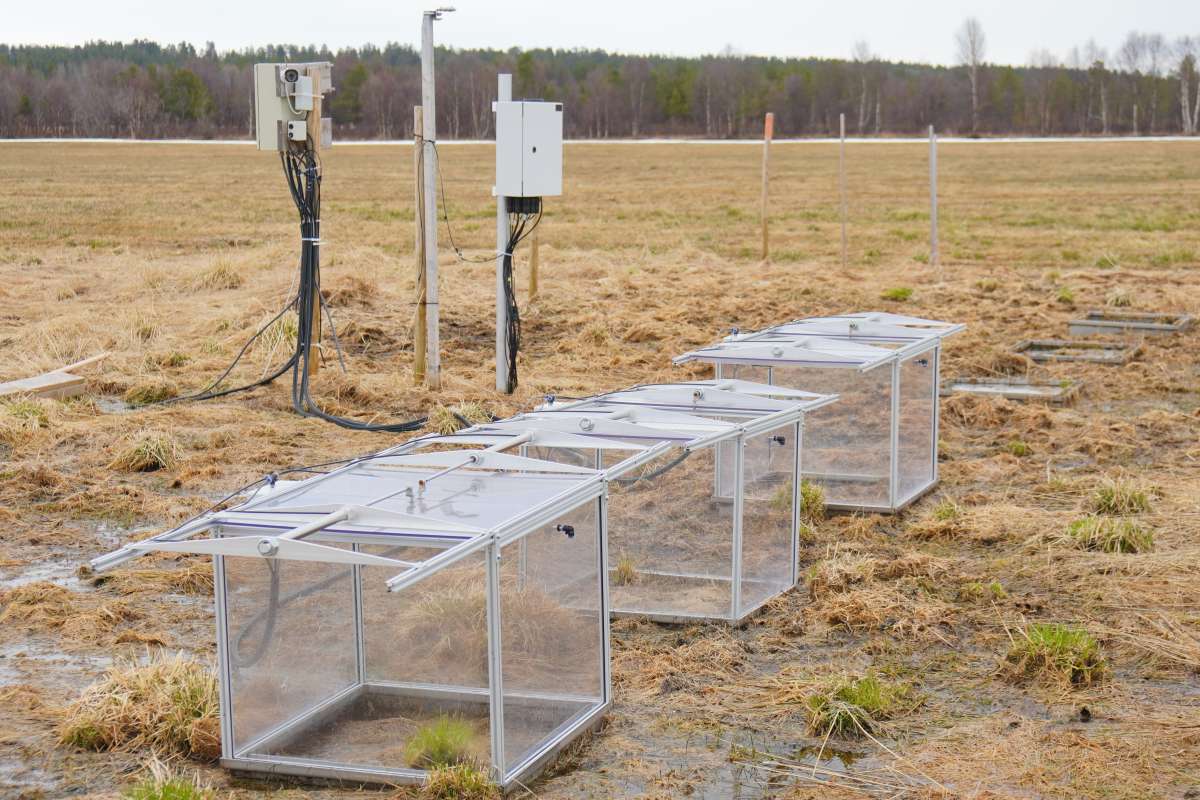

This was the background for the project “Sustainable Production of Turfgrass”, in which NIBIO collaborated with Norwegian sod producers to document actual soil removal.

How much soil is removed with turfgrass?

In 2023 and 2024, the researchers analysed 240 turf rolls from twelve producers. The analyses showed that, on average, 3.6 kilograms of soil mineral matter l were removed per square metre of turfgrass.

Soil mineral matter refers to soil of mineral origin – that is, soil derived from the weathering and breakdown of rock and stone – as opposed to organic soil, which is formed from the decomposition of plants and animals.

“The results showed considerable variation, ranging from 0.7 to 6.9 kg per square metre.”

“Whether the average of 3.6 kg/m2 is high or low depends on what you compare it with,” says Aamlid.

International studies from Europe and the United States show average values of roughly twice this amount. A German study, for example, found that sod harvest removed an average of seven kilograms of mineral matter per square metre.

According to Aamlid, the main explanation is that Norwegian turfgrass is usually allowed to grow for a longer period before sod harvest.

NIBIO’s surveys showed that the average age of turfgrass at sod harvest in Norway was 27 months, compared with 18 months in the German study.

“The extra time allows the turf to build up more organic matter, and less soil is removed during cutting,” Aamlid explains.

Comparison with other agricultural production

Soil removal is not unique to sod production. When harvesting other crops such as potatoes, carrots or swedes, some soil will always be removed from the field.

In cereal production with conventional autumn ploughing, Norwegian studies show that erosion losses can amount to one to two kilograms per square metre over a two- to three-year period – equivalent to a turfgrass production cycle. Most of this erosion loss is now avoided through reduced tillage.

“In sod production, the soil is usually tilled every second or third year only. This results in very little erosion,” says Aamlid.

What can sod growers do?

The variation observed among turfgrass rolls shows that sod growers have much to learn from each other when it comes to reducing the amount of soil loss.

“This includes, among other things, choosing the optimal sod harvesters. Sod grower should avoid cutting two wide rolls at the same time,” says Aamlid.

The waste management company Lindum participated in the project to investigate whether sod growers could make use of various types of residual organic products such as composts or digestates. The trials showed that the application of a moderate amount, (20 tons of dry matter per ha) in sludge compost or food-waste digestate before sowing resulted in slightly better turf quality and somewhat less soil removal during cutting. At the same time, their use or certain organic products caused challenges related to nutrient content, impurities and application uniformity.

“In one of the compost batches, we found both textile rags and an old mobile phone,” says Aamlid.

Another way to compensate for mineral matter removed in sod rolls may be to apply inorganic soil amendments, such as sand, rock flour or crushed brick.

Together with NIBIO, the turfgrass producer Utomhus Østfoldgress has developed a soil amendment based on crushed brick.

“The project has provided us with data that show how we can operate sustainably. Crushed brick replaces lost mineral matter, makes our turfgrass rolls lighter, and increases soil fertility,” says Managing Director Ole Christian Trandem.

“To compensate for the removal of 3.6 kilograms of mineral matter in turfgrass rolls, it is necessary to apply a 2–3 mm thick layer before sowing.”

Grass as a soil builder

Aamlid emphasises that the grass grown for turfgrass sod production is, by itself, soil-improving.

“Turfgrass produces large amounts of roots and clippings that enhance soil fertility when returned to the soil.”

In this project, the grass produced clippings corresponding to 1.5 kilograms of dry matter per square metre from sowing to cutting.

“This means that soil used for turfgrass sod production largely rebuilds what is removed and does not lose its long-term productive capacity,” Aamlid concludes.

Contacts

The project ‘Sustainable turfgrass sod production

The project “Sustainable Production of Turfgrass Sod” is a collaborative effort between NIBIO, the Turfgrass Sod Group in the Norwegian Horticultural Association, and the waste management company Lindum.

The main goal is to contribute to sustainable turfgrass sod production in Norway without degrading the soil’s productive capacity.

The project is funded by the Norwegian Agricultural Authority and led by Research Professor Trygve S. Aamlid at NIBIO Landvik.

Contacts

Publications

Abstract

Abstract The primary benefits of turfgrass sod include rapid greenery and soil coverage, but its production causes concerns about soil losses at production sites. Soil adheres to the grass root system during harvesting and is removed from the sod farm, which in the long run might lead to soil degradation on the sod farm. In this study, we investigated sod thickness and the removal of organic and mineral matter when harvesting 24 fields representing 12 Norwegian sod farms in 2022 and 2023. On each field, 10 sod strips were randomly chosen, and five sod plugs were collected from each strip. Sod thickness was measured using a sliding gauge. Sod mineral matter (SMM: soil and thatch mineral matter) and sod organic matter (SOM: soil and thatch organic matter) contents were quantified by loss on ignition at 550°C. Management and field properties were also documented. Results showed an average amount of mineral matter in the sod strips of 36 Mg ha −1 for all fields but with significant variation among fields ( p < 0.001). The average SOM content was 10 Mg ha −1 . Mean sod thickness was 15.4 mm and had a strong correlation with SOM ( r = 0.8) but only a moderate correlation with SMM ( r = 0.6). Soil water content and surface hardness at harvest affected sod thickness and SMM only slightly. Sod harvesters with twin heads harvested significantly thicker sod strips and removed more mineral matter than harvesters with single cutting heads. Soil texture did not have a significant impact on sod thickness or mineral matter removal.