Hans Ragnar Norli

Chief Engineer

Biography

Born and raised in Sandnes, Rogaland (Norway). Upper Secondary School: Natural Science Line 1981, Agder District High School: College College in Analytical Chemistry 1984, UiO: Master of Science 1986, Main Subject in Analytical Chemistry, MSc. 1989.

Abstract

This paper investigated the possibility of leaving out the traditional clean-up step in the QuEChERS procedure and analysing non-cleaned extracts from fruit, vegetables and cereals with a combination of gas chromatography-tandem mass spectrometry (GC-MS/MS), back-flush technology and large-volume injection. By using calibration standards in cucumber matrix, recovery and precision were calculated in lettuce, orange and wheat for 109 pesticides at 0.01 and 0.1 mg kg−1 in two sets of samples: one with and one without clean-up. For both spiking levels, 80–82% of the pesticides in the non-cleaned extracts and 80–84% of the pesticides in the cleaned extracts were within the acceptable recovery range of 70–120%. Precision data for both levels showed that 95% of the pesticides in the non-cleaned extracts and 93–95% of the pesticides in the cleaned extracts had RSDs below 20%. Recovery and precision data were determined using a two tailed t-test (p = 0.05). By using calibration standards in the respective matrix, we studied if the non-cleaned calibration standards gave an extra matrix effect compared with the cleaned standards by using the slope from calibration graphs and plotting the calculated extra matrix effect minus 100 for each compound. The results showed that for 79% of the pesticides, the extra matrix effect minus 100 was within the acceptable range of −20% to 20%. Five European Union proficiency tests on rye, mandarin, rice, pear and barley, respectively, from 2010 to 2012 were reanalysed omitting the clean-up step and showed satisfactory results. At least 70 injections of non-cleaned extracts were made without detecting any increased need for maintenance during the experimental period. Analysing non-cleaned QuEChERS extracts of lettuce, orange and wheat are possible under the conditions described in this paper because recovery, precision and specificity showed satisfactory results compared with samples subjected to traditional dispersive clean-up.

Abstract

No abstract has been registered

Abstract

Angrep av plantepatogene sopp og nematoder kan redusere avling og kvalitet av norskdyrket korn. Soppsjukdommer i korn kan til en viss grad bekjempes ved bruk av soppmidler (fungicider) men ingen kjemiske midler er godkjente mot nematoder i Norge. Vi har analysert innhold av glukosinolater og isotiocyanater i røtter og blader fra 12 ulike korsblomstra vekster. Noen av de korsblomstra vekstene produserte spesifikke kjemiske forbindelser (allyl-isotiocyanat) som i våre forsøk viste seg å kunne hemme vekst av plantepatogene sopp og nematoder som forekommer i korn. Vi observerte redusert overlevelse av sopp på kornrester i jord etter innblanding av oppkutta blader fra korsblomstra vekster i jorda (veksthusforsøk). Vi påviste derimot ikke noen effekt på overlevelse av nematoder (egg) i jord. Vi ønsker videre å studere overlevelse av sopp og nematoder i jord/halmrester i feltforsøk med utvalgte korsblomstra vekster som fangvekst/ettervekst i korn (i potensielle fremtidige prosjekt)

Abstract

Angrep av plantepatogene sopp og nematoder kan redusere avling og kvalitet av norskdyrket korn. Disse skadegjørerne kan til dels bekjempes ved bruk av kjemiske plantevernmidler. I 2023 startet vi opp et prosjekt med formål om å identifisere «grønne» metoder for å bekjempe plantepatogene sopp og nematoder i korn, som et alternativ til kjemiske plantevernmidler. Prosjektet har kortnavnet: «Grønt plantevern» og er finansiert av Landbruksdirektoratet. Våre kjemiske analyser av korsblomstra fangvekster dyrket i Norge viser at plantene inneholder en rekke glukosinolater som kan hydrolysere til mange ulike bioaktive isotiocyanater, hvis effekt mot planteskadegjørere fortsatt er lite studert. Våre undersøkelser har vist at sennepskål produserer allyl-isotiocyanat som kan hemme overlevelse og utvikling av sopp og nematoder som er vanlig i norsk korn. Våre forsøk viste dessuten en tendens til at innblanding av nettopp sennepskål kan redusere overlevelse av plantepatogene sopp og nematoder i planterester og jord. Vi fikk også en indikasjon på at forreddik kan hemme overlevelse av plantepatogene sopp i jorda. Vi håper at resultatene fra dette prosjektet kan danne grunnlag for et større prosjekt der en kan gjennomføre feltforsøk for å undersøke om dyrking av korsblomstra vekster som fangvekst/ettervekst i korn kan bidra til å redusere smittepresset av sopp og nematoder i skifter med ensidig korndyrking.

Abstract

No abstract has been registered

Division of Biotechnology and Plant Health

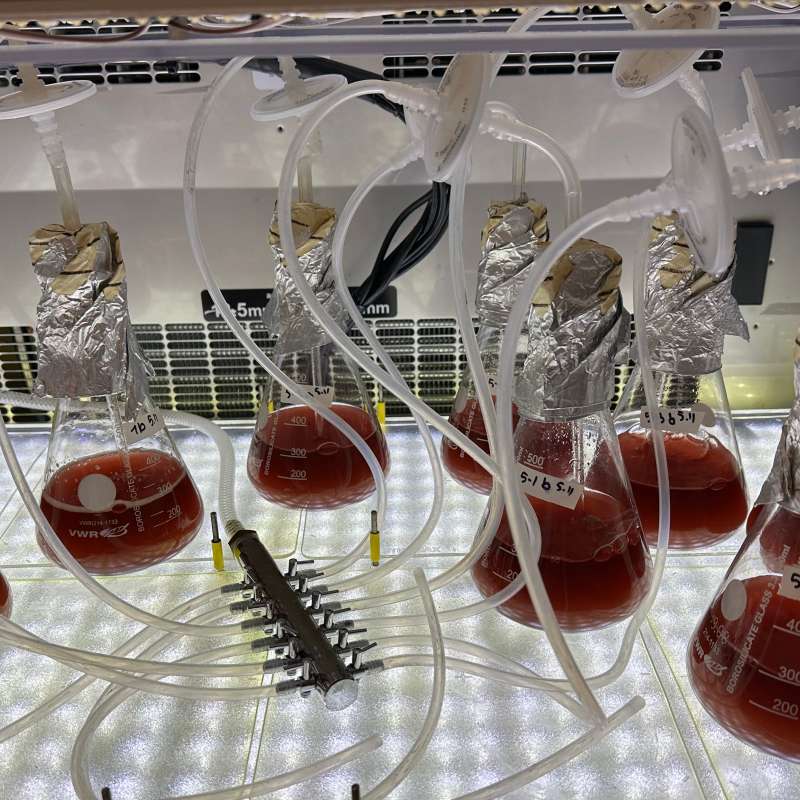

Microalgae contributions to future protein and fatty acid rich feed for Norwegian chicken at industrial scale - ALGEKYLLING

The main goal of the project is to create a knowledge and technology platform for production and use of chicken feed with proteins and polyunsaturated fatty acids (PUFA) from Norwegian microalgae biomass. The project consortium includes the whole production/value chain.

Division of Biotechnology and Plant Health

MikRho - Establishing Rhodomonas culture with beneficial microbiome adapted to industrial production

As one of the largest microalgae producers in Norway, CFEED contributes to sustainable feed solutions through its production of microalgae and the copepod