Division of Environment and Natural Resources

PacKnoPlast - Sustainable decision-making for food packaging given consumer rejection of plastic

End: jun 2022

Start: apr 2019

The project aims to develop environmentally friendly food packaging solutions where the use of plastic packaging is limited to where plastics is environmentally preferable to other materials and needed to preserve food quality through distribution, storage and use.

Project participants

Claire CoutrisThe project will gain new knowledge and capacity in the Norwegian food industry about the role of plastics as a food-packaging material in a sustainability perspective. Focus will be on the functions of plastic packaging related to preserving and distributing the product, the risk of wrongful disposal and environmental impacts through the value chain.

| External project link | Project website at Cristin |

| Start - end date | 01.04.2019 - 30.06.2022 |

| Project manager | Cecilia Askham |

| Project manager at Nibio | Erik J. Joner |

| Division | Division of Environment and Natural Resources |

| Department | Bioresources and Recycling Technologies |

| Partners | Q-meieriene, ROAF, De Paauw/Rodepa Plastics, Noprec, Bellona, Grønt Punkt Norge, Emballasjeforeningen, Gartnerhallen, No Waste!, FSLCI, Lindum, VESAR, NORSUS, NIVA, NOFIMA, NORNER, NIBIO |

| Total budget | 11.2 Million NOK |

| Funding source | Norwegian Research Council (Grant 299326), Bama and partners |

Our role in PacKnoPlast

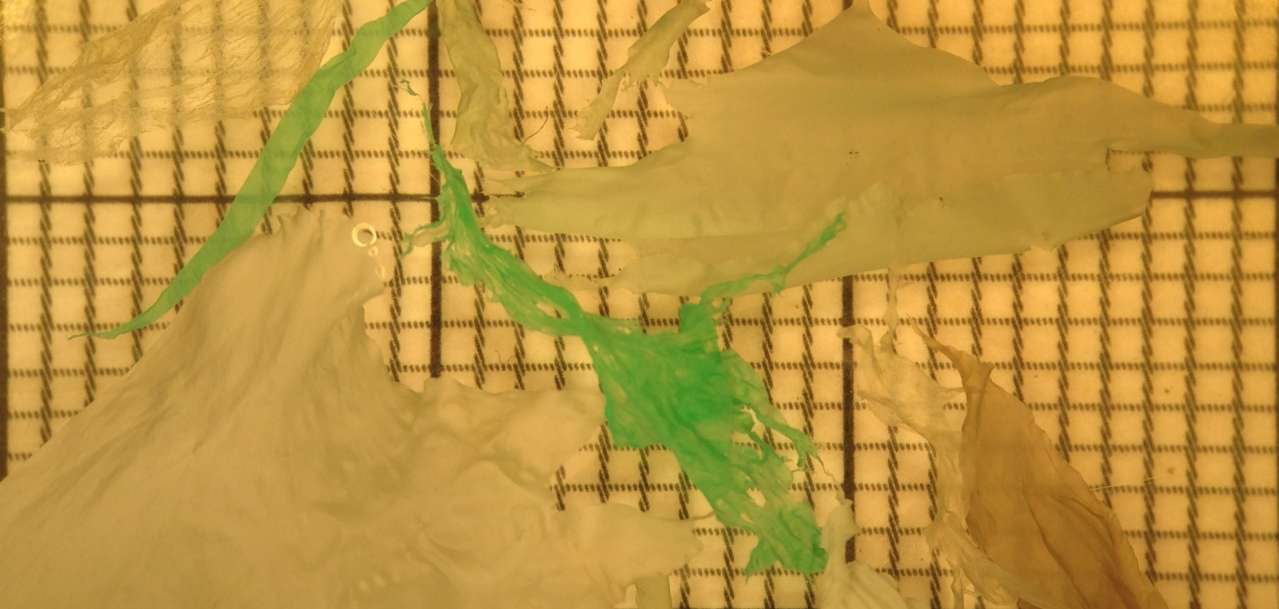

NIBIO is involved in mapping and characterizing the amounts and quality of wrongly sorted post-consumer plastic packaging. This is based on the analysis of biogas digestate from Norwegian biogas production plants, where plastic particles are recovered, identified and quantified.

NIBIO is also assessing the fate, fragmentation and environmental risk of (micro)plastics entering soils.

Publications in the project

Authors

Claire CoutrisAbstract

No abstract has been registered

Authors

Claire CoutrisAbstract

No abstract has been registered

Abstract

Resirkulering av organisk avfall er et prioritert tema innen sektorene landbruk, klima og avfall, og skal bidra til at organisk materiale og næringsstoffer føres tilbake til jord. Dette kan motvirke en langsiktig trend der moldinnholdet i matjorda gradvis blir lavere, noe som ser ut til å bli et økende problem i forbindelse med klimaendringer og økende behov for mat. Tilbakeføring av næringsstoffene i organisk avfall skal på sin side bidra til å redusere behovet for mineralgjødsel, og dermed minske behovet for energikrevende gjødselproduksjon og uttømming av begrensete ressurser av mineralsk fosfat.

Abstract

Organic industrial and household waste is increasingly used in biogas plants to produce bioenergy, generating at the same time extensive amounts of organic residues, called biogas digestates. While agricultural soils can benefit from the organic matter and nutrients, in particular nitrogen and phosphorus, contained in biogas digestates, we need to assess the environmental and health risks associated to the undesirable substances that may come along. Among those, only a few are covered by actual regulations. For instance, the quantity of plastic materials below 4 mm in biogas digestate is currently not limited to any threshold, despite its likely occurrence in organic waste (waste bag remains and wrong waste sorting) and persistence in the environment. The aim of our study was identify and quantify plastic materials in digestates from Norwegian biogas plants, that are using various types of organic waste sources (e.g. sewage sludge, food waste, animal manure). In addition, a lab-scale experiment was set up to assess the physical and chemical transformations undergone during biogas processes by plastic materials commonly found in digestates. The methods used in our study included simultaneous thermal analysis coupled to Fourier transform-Infrared spectroscopy (for analysis of polymer composition), scanning electron microscopy (for assessment of physical transformations), and a range of physical and chemical extractions for recovering plastic materials from biogas digestates. While all digestates complied with current regulations, plastic particles with a size of 0.2-3 mm made up to 1% (on dry mass basis) of the samples analyzed. Analysis of the polymeric composition of the recovered plastic fragments confirmed that they originated both from the waste bags themselves (shredded during the first steps of waste handling) and from wrong waste sorting. In addition, the lab-scale biogas treatment was shown to considerably change the structure of the studied plastic materials, illustrating a pathway for the formation of secondary microplastics. Some analytical challenges linked to the size and aging of the plastic materials, as well as the complex composition of the digestates, will be discussed. From a broader perspective, a few options will be presented to address the presence of plastic materials in biogas digestates, and thereby minimize the risk associated to their use as soil amendment.